What will you learn with The ChainSim simulation?

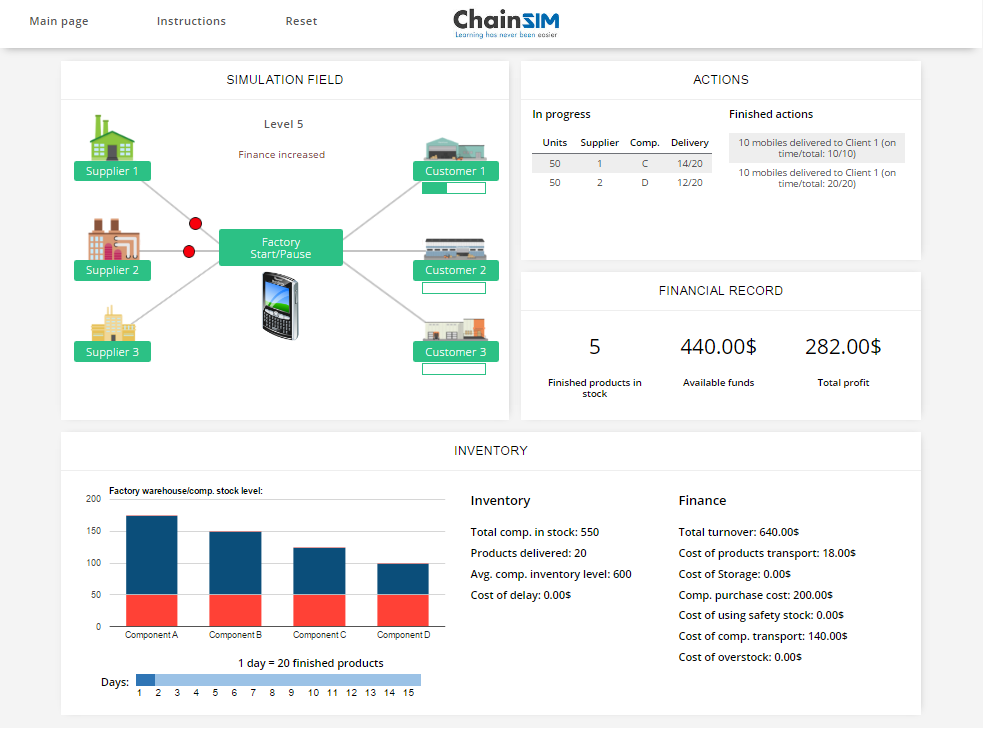

We improve our customers’ Production, Logistics and Supply Chain Planning learning processes by utilizing our ChainSim simulation systems. Simulation enables our clients to use their resources for better competitive advantage in teaching and to support all academic units in their assessment of student learning/development process.

.After completing ChainSim five level courses, students should:

- Demonstrate an ability to apply general management know-how in practical business situations

- Have the skills required to use Lean tools to decrease expenses and improve efficiency in Supply Chain, and Manufacturing sectors

- Measuring cost and performance in Supply Chains

- Understanding the basic frame and key issues of Supply Chain and Production Planning

- Define the supply chain concepts and key managerial processes

- Develop analytical methodologies for Supply Chain analysis

- Develop systematic thinking and making students understand that every decision affects the whole chain

- Learn how to optimize the basic cost of procurement, inventory management and transport logistics

- Supplier selection, assessment, sourcing strategies, total cost optimization

- Analyze the manufacturing operation of a firm

- Learn and test how to apply Lean manufacturing concepts

- Improves decision making in teams

To get manufactured goods to flow, the lean enterprise takes the critical concept of JIT ( just in time) and level scheduling and carries them all the way to their logical conclusion by putting products into continuous flow wherever possible.

ChainSim simulation helps to understand principles, theories and practices of material requirements planning (MRP) and supply chain management, operations management, and LEAN thinking, critically evaluate and link those to various aspects of performance (financial measures as well as physical inventory aspects). Simulation can be paused, whereas real life cannot. Pausing allows more time for students to assess what’s going on.